Glossary

Primary HPWHs

Annual Emissions Reduction

Ecosizer runs two annual simulations with identical systems, one baseline without load shifting and one with load shifting. Each simulation uses ambient conditions to calculate heat pump efficiency and power draw, which is then mapped to the chosen climate zone's emission rate for each hour.

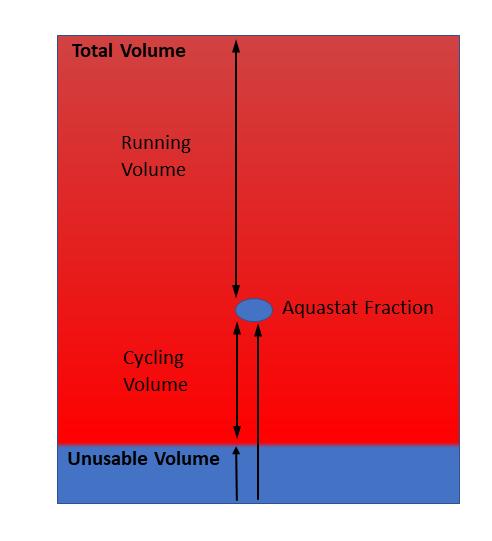

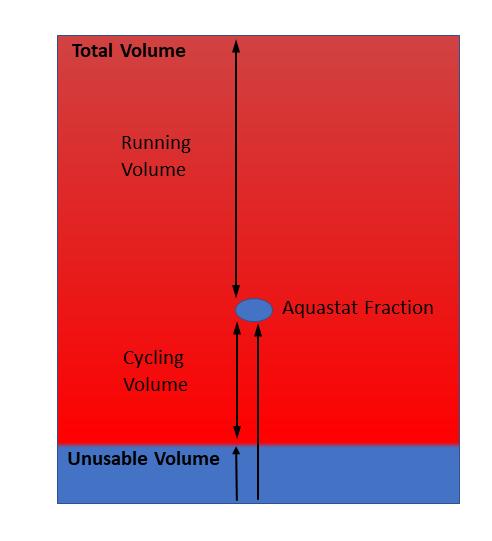

Aquastat Fraction

This is the point in the entire primary storage volume where the temperature trigger (aquastat) for cycling on the heat pump water heaters is placed. The default is to place this aquastat so that 40% of the primary storage is used when the heat pump equipment is triggered to cycle on. This is controlled by where the aquastat port is on the storage equipment that is being purchased.

Decreasing the fraction will result in the HPWH running more frequently and a smaller primary storage volume.

Increasing the fraction means less storage is available to provide hot water while the HPWH equipment is recharging the primary storage, and a larger storage volume.

During load shift scenarios, you may decrease the fraction to decrease the total tank volume. The Ecosizer will notify you if the aquastat is too low to allow for the minimum cycling time of a HPWH.

Aquastat Fraction

The heat pump water heaters are controlled to turn on and off with temperature sensors located in the storage tank -- these are called aquastats. The aquastat faction is the % of the tank water volume that is allowed to fall below the aquastat's setpoint before the heat pump begins an ON-Trigger. Installing three temperature sensors -- at the top (65-85% of volume), middle (30-45% of tank volume), and bottom (10-25% of tank volume) -- allows for effective management of the heat pump water heaters operations during shed, normal, and load up operating modes respectively.

Aquastats

Drastic modifications of these aquastat locations may lead to system malfunctions. Decreasing the normal aquastat may lead to short cycling, while lowering the shed or increasing the load up aquastat will lead to underutilized storage volume.

Building Type

Type of building to be sized.

Custom Hot Water Load

Calculate only this Custom Load (disable Multifamily Load)

Disables the multifamily load (next section) and only uses these hourly load inputs.Add Custom Load to Multifamily Load

Combines the custom load added via these hourly inputs and the multifamily load (next section).Multifamily Load only (disable Custom Load)

Disables the hourly load inputs in this section and calculates just the multifamily load. We’ll remember your custom load settings if you decide to turn them back on.

Design Cold Water Temperature

This is the coldest water temperature supplied by incoming city water.

Increasing this value means the HPWH has a lower temperature lift to the hot water supply temperature, and the required heating capacity will decrease.

Drawdown

This is the fraction of the primary storage volume that is filled with hot water at the storage temperature.

The drawdown is used to check that the primary storage volume between the aquastat and the bottom of the effective storage volume is large enough that the primary HPWHs can cycle for at least 10 minutes without any hot water draws. Having a cycling volume greater than this minimum helps build a robust CHPWH system and adds some safety in the storage volume.

EcoPort Commands

To achieve load shifting, heat pump water heaters need to change their operation throughout the day, charging thermal storage before a shift and riding through shift periods using storage hot water. Heat pump water heaters will receive a signal through an EcoPort (defined by CTA-2045-B) or equivalent communication instrument, but the control system needs to be programmed to respond to the commands. At a minimum, heat pump water heating systems need control changes that correspond to Normal, Load Up, and Shed commands defined in this table.

HPWH Outlet

HPWH Outlet is the temperature of the water generated by the HPWH, which may be increased during load up to store water at a higher energy density The HPWH outlet temperature will influence the water temperature in the top of the tank that is leaving the tank and being sent to a swing tank and/or thermostatic mixing valve.

Hot Water Storage Temperature

This is the setpoint temperature of the primary heat pump water heaters, or the hottest temperature provided by the primary heat pump equipment. There is no default. If you are designing a swing tank system you should use at least 140F.

Input Method

These options allow you to toggle between two ways to provide number of people (building occupants) and number of apartments information.

Using Total People & Apartments requires just those two values.

Using Apartment Size & Occupancy Rates allows more control over apartment types, occupancy rates (people per unit size), and gallons of hot water used per day per person. Suggested values are also provided from California and ASHRAE occupancy data.

Kilograms of CO2 emissions per kilowatt-hour

Incentive eligibility is determined by system's ability to offset carbon emissions by greater than or equal to 5kg CO2/kWh load shift capacity annually. See 'Annual Emissions Reduction' and 'Load Shift Capacity' for details of this calculation.

Load Shift Capacity

Thermal storage is calculated using the aquastat setpoint, aquastat fraction, and average incoming city water temperature from the chosen climate zone. The volume between the load up and shed aquastat is used as the volume metric rather than the whole tank because it accurately reflects the amount of storage that can be used as a thermal battery during a designated shed period.

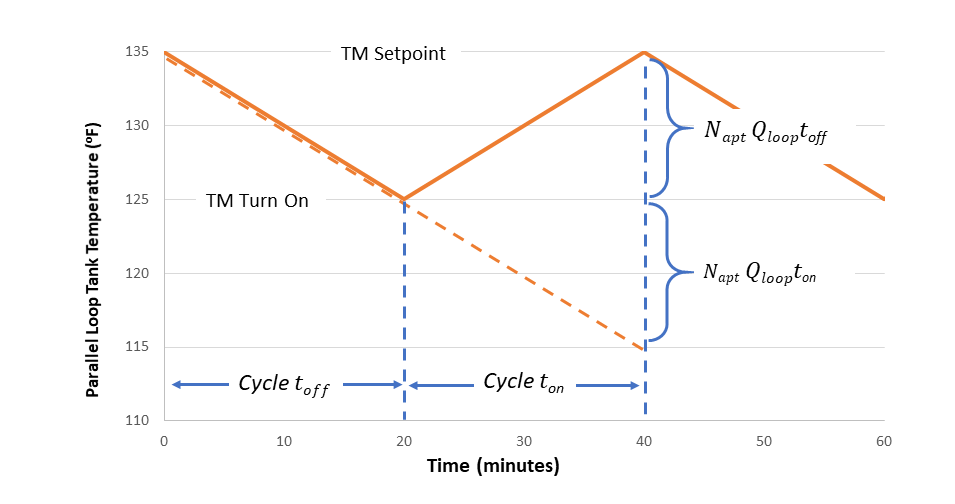

Load Shift Sizing

The load shift function allows you to block out part of the day when the heat pump water heaters will not run. The storage volume and heating capacity necessary to meet the load is sized similarly as in the primary system but accounting for period(s) where the heat pump water heaters will not run as requested by utility signals. This necessarily means that the storage volume must be higher so that the volume in the primary storage can provide the building occupants with hot water for the period when the heat pumps are prevented from running, and can meet any peaks after the end of the load shift period(s).

Load shift systems can grow quite large, in part due to the aquastat fraction being larger than needed. The aquastat fraction can be turned down in many load shift cases to account for a much larger than needed volume for the HPWH to cycle through.

Load Up Aquastat Fraction

This is the point in the entire primary storage volume where the temperature trigger (aquastat) for cycling on the heat pump water heaters is placed during a shed period.

Decreasing the fraction will result in the HPWH running more frequently and a smaller primary storage volume.

Increasing the fraction means less storage is available to provide hot water while the HPWH equipment is recharging the primary storage, and a larger storage volume.

During load shift scenarios, you may decrease the fraction to decrease the total tank volume. The Ecosizer will notify you if the aquastat is too low to allow for the minimum cycling time of a HPWH.

Load Up Controls

Controls corresponding to CTA-2045-B defined Load Up and Advanced Load Up. Typically systems decrease the Aquastat Fraction (i.e. a smaller % volume of the tank is below aquastat setpoint) and increase the heat pump water heaters outlet temperature setpoint (if possible).

Load Up Hours

The number of hours it will take the system to Load Up the storage after turning off in Normal Operation. This value may drive the required heating capacity if it is greater than the capacity needed to meet the daily load.

Load Up Hours

The maximum number of hours it could take the system to heat the storage tank during a Load Up command (i.e. the number of hours for the % volume of the tank to be at or above setpoint, based on the load up aquastat fraction and OFF-trigger) This value may drive the required heating capacity if it is greater than the capacity needed to meet the daily load.

Load Up Temperature

This is the load up setpoint temperature of the primary heat pump water heaters, or the hottest temperature provided by the primary heat pump equipment during a load up period.

Maximum number of meals per hour

Maximum number of meals per hour in the building served by the heat pump water heater.

The peak daily usage and load shape are derived from ASHRAE Applications Handbook 2019.

Maximum number of meals per hour

Maximum number of meals per hour in the building served by the heat pump water heater.

The peak daily usage and load shape are derived from ASHRAE Applications Handbook 2019.

Multi Pass

Multipass equipment can be a split system which draws and returns water near the bottom of the tank, similar piping to a gas boiler, or unitary equipment where the condenser is wrapped around the tank. Multipass HPWHs heat water in stages as opposed to a single pass through the HPWH and are typically less stratified

Multi Pass

Multipass equipment can be a split system which draws and returns water near the bottom of the tank, similar piping to a gas boiler, or unitary equipment where the condenser is wrapped around the tank. Multipass HPWHs heat water in stages as opposed to a single pass through the HPWH and are typically less stratified

Multi Pass

Multipass equipment can be a split system which draws and returns water near the bottom of the tank, similar piping to a gas boiler, or unitary equipment where the condenser is wrapped around the tank. Multipass HPWHs heat water in stages as opposed to a single pass through the HPWH and are typically less stratified

Normal Controls

Normal operating controls when no command is sent or a return to normal command is sent to the system.

Number of Temperature Maintenance HPWHs

Number of apartments

Total number of apartment units in the building.

An increase in the number of apartments in a building will result in increased temperature maintenance losses for a given Recirculation Loop Heat Loss.

Number of apartments

Total number of apartments in the building served by the heat pump water heater.

The peak daily usage and load shape are derived from ASHRAE Applications Handbook 2019.

Number of beds

Total number of beds in the building served by the heat pump water heater.

The peak daily usage and load shape are derived from ASHRAE Applications Handbook 2019.

Number of people

Total number of people in the building served by the heat pump water heater. Load shape based on Ecotope research.

The number of people is multiplied by the gallons per person to get peak daily usage. The daily profile for this sizing methods is derived from Ecotope research.

Number of people

Total number of people in the office building served by the heat pump water heater.

The peak daily usage and load shape are derived from ASHRAE Applications Handbook 2019.

Number of rooms

Total number of rooms in the building served by the heat pump water heater.

The peak daily usage and load shape are derived from ASHRAE Applications Handbook 2019.

Number of students

Total number of dorm rooms in the building served by the heat pump water heater.

The peak daily usage and load shape are derived from ASHRAE Applications Handbook 2019.

Number of students

Total number of dorm rooms in the building served by the heat pump water heater.

The peak daily usage and load shape are derived from ASHRAE Applications Handbook 2019.

Number of students

Total number of students in the building served by the heat pump water heater.

The peak daily usage and load shape are derived from ASHRAE Applications Handbook 2019.

Number of students

Total number of students in the building served by the heat pump water heater.

The peak daily usage and load shape are derived from ASHRAE Applications Handbook 2019.

Number of students

Total number of students in the building served by the heat pump water heater.

The peak daily usage and load shape are derived from ASHRAE Applications Handbook 2019.

OFF-Trigger

OFF-Trigger is a suggested temperature setpoint that will turn the heat pump water heater OFF at the aquastat fraction indicated (i.e. completion of recovery cycle). The current value is not used in sizing and only a suggestion. The engineer and manufacturer should be consulted on appropriate values to prevent short cycling while still achieving load shift.

ON-Trigger

ON-Trigger is a suggested temperature setpoint that will turn the heat pump water heater ON at the aquastat fraction indicated (i.e. aquastat setpoint and start of recovery cycle). The current value is not used in sizing and only a suggestion. The engineer and manufacturer should be consulted on appropriate values to prevent short cycling while still achieving load shift.

One Cycle Off Time

This controls the temperature maintenance tank volume and is the expected time (in hours) that the temperature maintenance equipment will be off between heating cycles. This is related to the difference between the Temperature Maintenance Setpoint and Turn On temperatures, and the Recirculation Loop Heat losses. In other words, the time that will elapse as the loop losses reduce the tank temperature from the setpoint to the temperature that will trigger the heat pump water heater to cycle on.

Parallel Loop Tank

Single-pass heat pump water heaters are most efficient when heating cool city water to hot storage temperatures, whereas multi-pass equipment can still operate efficiently when incoming water temperatures are around 120F. A parallel loop configuration is one strategy used to isolate the temperature maintenance task from the task of heating the primary storage. A parallel loop tank is an electric resistance element or a multipass heat pump that is piped in parallel with the primary system, specifically to handle the temperature maintenance load.

Peak Gallons per Day per Person

Use this area to provide information on the maximum gallons of hot water used per day by each building occupant.

The User Defined option allows you to choose a value of your choice between 20 and 49 gallons per day per person. Using the California By Bedroom option is only possible when entering the number of units by size (input method), as each unit will have a different value aligned with the Title 24 Software CBECC-Res. Using this method means also using the CA occupancy ratios.

ASHRAE Low is described as an apartment building with a mix of demographics: all occupants working; one person working, while one stays at home; seniors; couples; middle income; higher population density.

Ecotope Market Rate with Low Flow Fixtures is based upon measured data from an Ecotope Inc. project, Stream Uptown, a building with 118 units. Data uses the 100% quantile for the peak draws during the given time periods.

ASHRAE Medium is associated with apartment buildings with a mix of occupant demographics: families; singles; on public assistance; single-parent households.

The number of people is needed to define how much hot water is used daily.

References

- http://www.bwilcox.com/BEES/cbecc2019.html

- 2015 ASHRAE HVAC Applications - Table 7, pg. 50.15.

Percent of Load Shift Captured

This adjusts the percent of days to meet the hot water demands of load shifting. For example, turning this down to 70% implies that only 70% of days will meet the hot water demand from load shift. This is achieved by scaling down the daily gallons per person to the 70th percentile value following a distribution acquired from 4 years of data from a market rate building in Seattle, WA. The median value at the 50th percentile is about 70% of the 100th percentile load.

Note that your storage requirement increases exponentially with increased load shift, represented by the curve behind the slider. So the closer to 100% you get, the larger the impact will be on storage requirements.

Primary - No Recirculation

Primary - No Recirculation is used for sizing a primary plant only.

Primary - No Recirculation

Primary - No Recirculation is used for sizing a primary plant only.

Primary Storage Volume (Gallons)

Recirculation Loop Flow Rate

The recirculation loop flow rate is the rate at which a recirculation pump moves hot water through the distribution loop in gallons per minute.

This is used along with the recirculation loop return temperature to calculate the recirculation loop heat loss rate.

Recirculation Loop Heat Loss

These are the losses associated with the recirculation loop expressed in Watts/apartment unit. Previously studied buildings show a median loss value close to 100 W/apt, with a 25th percentile of ~66W/apt, and a 75th percentile of ~175W/apt. Ideally, building and plumbing design will minimize this load. This is an area of building science that deserves additional research to better understand typical recirculation losses, and how to minimize them.

Increasing the recirculation loop heat loss rate will increase the temperature maintenance load expected and thus increase the temperature maintenance heating capacity and storage volume.

References

- Kintner P., and B. Larson (2019). Literature Review of Multifamily Central Domestic Hot Water Distribution Losses. Prepared for NEAA.

Recirculation Loop Return Temperature

The recirculation loop return temperature is the temperature of hot water when it returns to the temperature maintenance plant.

This is used along with the recirculation loop flow rate to calculate the recirculation loop heat loss rate.

Recommended Minimum Heating Capacity

The recommended minimum heating capacity is the minimum needed average output capacity of the selected equipment at the design cold air temperature in your climate zone. Note that you must also account for manufacturer specific defrost penalty. The recommended minimum heating capacity is found assuming a maximum compressor runtime of 16 hours per day, based on manufacturer recommendations, and provides a built-in safety factor for days where the total gallons of hot water used may be greater than the max used in this sizing tool. The recommended minimum heating capacity is the heating capacity needed on the design day; this need not be provided entirely by heat pump water heaters but can be supplemented by electric resistance water heaters to lower costs. It is recommended to use an additional heat pump or two for redundancy in case one heat pump goes down; without proper monitoring the system can provide hot water with back up heaters but the overall performance of the system will be reduced.

Recommended Minimum Parallel Loop Heating Capacity

The design of a parallel loop tank system must balance the expected load with the volume of the loop tank and the capacity of the temperature maintenance heating system. Too little capacity will lead to cold water being circulated. Too large of a capacity could lead to short-cycling of equipment - a run time less than 10 minutes. The sizing of the heating capacity for a parallel loop tank is designed to exceed the recirculation loop losses using a safety factor.

The minimum parallel loop tank heating capacity is calculated from the total temperature maintenance load times the safety factor, which defaults to 1.75.

Recommended Minimum Parallel Loop Tank Volume

The recommended minimum parallel loop tank volume is designed to coast from the setpoint to the turn on point over the time period defined by the one cycle off time.

Recommended Minimum Swing Resistance Element

The swing tank resistance element is sized to meet the recirculation loop load without hot water input from the primary system because it must maintain the supply temperature to occupants even during periods of low DHW use.

The minimum swing tank resistance element is calculated from the total temperature maintenance load times the safety factor, which defaults to 1.75.

Recommended Minimum Swing Tank Volume

Sizing of the swing tank volume is mostly irrelevant at predictable temperature maintenance values. The recommendation here is given as a function of the number of apartments. If care is taken to reduce the temperature maintenance load below 50 W/apt, a system can benefit from increased swing tank volume, where increasing from an 80 gallon tank to a 300 gallon tank can reduce resistance element use by about 12%.

Recommended Minimum Tank Volume

The recommended minimum tank size is the tank volume found assuming a worst-case scenario that when entering a peak hot water event the CHPWH system has not heated the entire volume of the tank and the hot water level is just below the aquastat. Then the remaining volume in the tank is calculated as the difference between the peak hot water event and the hot water generation rate, defined by the total daily hot water usage and the maximum compressor runtime (assumed 16 hours per day).

This can be further optimized by changing the aquastat fraction. However, keep in mind that the aquastat fraction is a variable of the actual design of the CHPWH system.

Schedule

Ecosizer simulates daily load shifting from 4pm-11pm. Even if a system is not sized for this, it is critical to extend scheduled shed periods past peak pricing in order to achieve CO2 emission savings. Emissions rates remain high several hours after peak pricing ends (typically around 9pm) and overall emissions savings rely on the ability to shed until at least 11pm on low to moderate domestic hot water use days.

Setpoint

Setpoint is the temperature of the water generated by the HPWH. Under Normal operation it is the same as the Hot Storage Temperature, but it may be increase during load up to storage water at a higher energy density.

Shed Aquastat Fraction

This is the point in the entire primary storage volume where the temperature trigger (aquastat) for cycling on the heat pump water heaters is placed during a shed period.

Decreasing the fraction will result in the HPWH running more frequently and a smaller primary storage volume.

Increasing the fraction means less storage is available to provide hot water while the HPWH equipment is recharging the primary storage, and a larger storage volume.

During load shift scenarios, you may decrease the fraction to decrease the total tank volume. The Ecosizer will notify you if the aquastat is too low to allow for the minimum cycling time of a HPWH.

Shed Controls

Controls corresponding to CTA-2045-B defined Shed and Critical Peak Event. Typically the system increases the Aquastat fraction to achieve a longer period without electrical use (i.e. a larger % volume of the tank is allowed to be below setpoint). Electric resistance elements should be locked out during a Shed Event. Electric resistance can be locked out with a relay or other control.

Grid Emergency, defined by CTA-2045-B should turn off the system completely.

Single Pass

Single pass equipment draws water from the bottom of the tank and heats to setpoint in one pass through the HPWH, returning the hot water to the top of the tank and maximizing stratification.

Single pass return to primary label

Single pass equipment can be a split system which draws and returns water near the bottom of the tank, similar piping to a gas boiler, or unitary equipment where the condenser is wrapped around the tank. Multipass HPWHs heat water in stages as opposed to a single pass through the HPWH and are typically less stratified

Supply Water Temperature

This is the water temperature supplied to the building occupants from the hot water system/plant. The default is set to 120F, an industry standard. If you are aligning sizing efforts with CA Title 24 software this should be increased to 125F.

Increasing the supply water temperature raises the reference temperature for what the occupants use. This will increase the storage volume as the hot water stored has less potential energy over the supply water temperature.

Swing Tank

A Swing Tank design is a proven technique to use the primary heat pumps to support the temperature maintenance load (Banks et al., 2020), while keeping the heat pump equipment isolated from the warm water returning from the recirculation loop. This design strategy is best suited for buildings with low temperature maintenance loop losses (< 60W/apt) and relies on increased storage volume (with tanks piped in series) to ensure storage stratification. Swing tank systems have an electric resistance element in the temperature maintenance tank as a backup safety factor. Sizing a swing tank system also means increasing the heating capacity and storage volume of the primary system. The temperature maintenance storage volume for the swing tank can be small.

References

- Banks, A, Grist, C., and J. Heller. 2020. CO2 Heat Pump Water Heater Multifamily Retrofit: Elizabeth James House, Seattle WA. Prepared for Washington State University Energy Program, under contract to Bonneville Power Administration

Swing Tank Element (kW)

Temperature Maintenance Setpoint

This term, the Temperature Maintenance Turn On, and the Cycle Off Time are critical to sizing a multi-pass heat pump water heater system. The Temperature Maintenance Setpoint is the temperature of the water serving the recirculation loop supply.

Increasing the temperature maintenance setpoint while holding the temperature maintenance turn on temperature (at 125F) will decrease the temperature maintenance tank volume as the stored energy density of the tank is greater.

Temperature Maintenance Storage Volume (Gallons)

Temperature Maintenance System Safety Factor

The safety factor the temperature maintenance heater will have over the temperature maintenance load.

A higher safety factor will increase the output of the temperature maintenance heater. If the safety factor was set to 1, the temperature maintenance heater and the temperature maintenance load would be in perfect balance.

Temperature Maintenance Turn On

This term, the Temperature Maintenance Setpoint, and the Cycle Off Time are critical to sizing a multi-pass heat pump water heater system. The Temperature Maintenance Turn On is the temperature of the water that will trigger the temperature maintenance to begin a heating cycle. In other words, the lowest temperature to which the temperature maintenance tank should be allowed to drop. This cannot be less than the supply temperature.